Installation

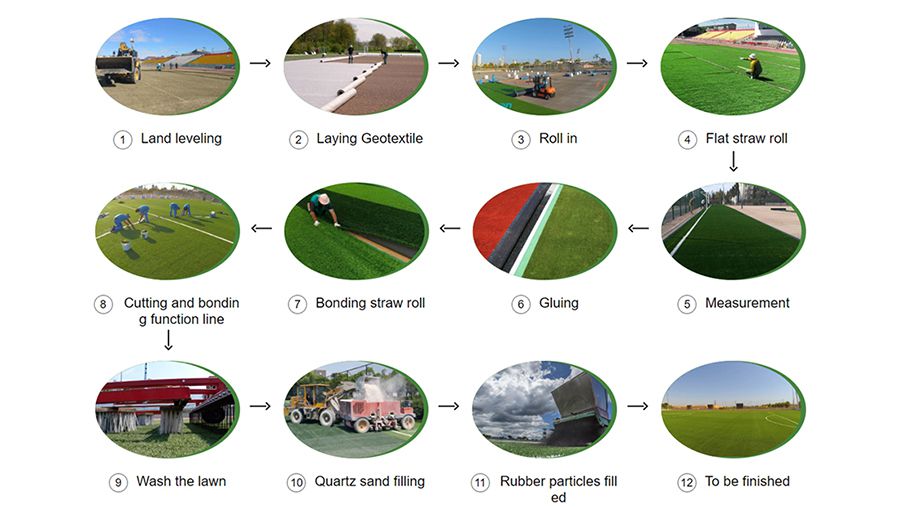

The installation of football artificial grass is based on ground foundation. Only when the density and flatness of the ground foundation meet our standards can we carry out next installation procedures. The slope range should be within 3‰-4‰ to ensure smooth drainage of ground water. Before the installation, the ground must be fully cleaned. The installation process can be boiled down to following procedures:

- Remove Existent Lawn Machines should be used to remove the lawn and then staff should further check the ground to ensure the surface is clean.

- Level the Land Machines should be used to improve the flatness and density of the ground, ensuring the ground surface is smooth and level enough.

- Install Sub-base Stones with appropriate sizes should be paved on the compacted land, with the lower layer paved with bigger stones while the upper one with smaller stones. After that, machines should be employed to press the stone base to make it dense enough. After the stone base has been built, concrete should be paved upon the base to make it harder. Along with the installation, drainage system should be put into place.

- Sub-base Examination After the installation of the sub-base, staff should measure the slope, flatness and hardness. Hardness can be tested by machines, while other specifications should be tested by the method of fixing wood piles every ten meters away.

- Installation of Artificial Lawn Firstly, bundles of artificial lawn should be spread out and to be installed in the next day.

Secondly, the fake grass should be cut to pieces with the same size and the joint of every piece should be carefully trimmed.

Thirdly, the synthetic grass should be paved on the field and the distance between different pieces should be smaller than two grasses. The direction of the fake turf and the grass fibers should be consistent.

Next, professional glues should be applied. The thickness of the gluing should be the same and the glue should not be applied repeatedly.

After gluing, a special tool should be used to press the fake turf to make it compact enough. After that, staff should inspect and trim the grass in the following three days.

Contact us for more information, specifications and tooling advice.

Installation Guide

| Yarn height (mm) | Gauge (Inch) | Quartz sand size (mm) | Rubber particle size (mm) | Suggested filling amount of quartz sand (kg/m2) | Suggested filling amount of SBR or EPDM(kg/m2) | Height after filling (mm) |

| 10 | 3/16 | 0.0-0.5 | / | 10 | / | 10 |

| 20 | 3/16 | 0.0-0.5 | / | 15 | / | 15 |

| 25 | 3/8 | 0.0-0.5 | 0.8-2.0 | 13 | 2-5 | 20 |

| 32 | 3/8 | 0.2 - 1.0 | 0.8-2.0 | 15-20 | 3-6 | 22 |

| 40 | 5/8 | 0.2 - 1.0 | 0.8-2.0 | 15-20 | 4-8 | 26 |

| 50 | 5/8 | 0.2 - 1.0 | 0.8-2.0 | 18-25 | 6-14 | 30-35 |

| 55/60 | 5/8 | 0.2 - 1.0 | 0.8-2.0 | 20-30 | 8-16 | 40-45 |

Taishan Artificial Turf Industry is a wholly-owned Subsidiary of Taishan Sports Industry Group since 1978. We are a one-stop leading manufacturer and wholesaler focusing on R&D, production and sales of artificial sports turf, leisure garden turf, multi-functional negative ion turf. After 46 years of development, Leling Taishan, as the first artificial turf manufacturer in China to obtain FIFA and FIH certifications, has built CHINA TOP 1 modern production base for high-end artificial turf manufacturing.